Without a doubt, machines and equipment will encounter certain problems in the future. After using them for weeks or even years, they will surely need some repairs. Let’s find out how you can detect some of their common hydraulic problems. After reading this article, then you might be able to solve them now on your own!

The hydraulic system keeps your mini excavators functional. It also makes the operators’ work easier. Without them, mini excavators would still clank and grind. They would still be dependent on using cables, chains, and gears to accomplish their work. Operators would also still push and pull cast-iron levers instead of tweaking joysticks.

You have now learned the relevance of hydraulic systems on your mini excavators. At this time, you are already aware of how important it is to keep them intact. In ensuring the good condition of mini excavators, refer to our guide below. We provided ways on how to quickly identify the first signs of hydraulic problems.

The Common Hydraulic Problems on Mini Diggers

1. High Fluid Temperature

System struggling to scatter heat often results in high fluid temperatures. This leads to an increase in heat load. When the fluid temperature exceeds 180°F (82°C), that can damage the seals. It will then start to degrade the fluid itself. That being said, operators must be observant to avoid reaching beyond the limit. They should ensure that the viscosity is not below the optimal value of the system.

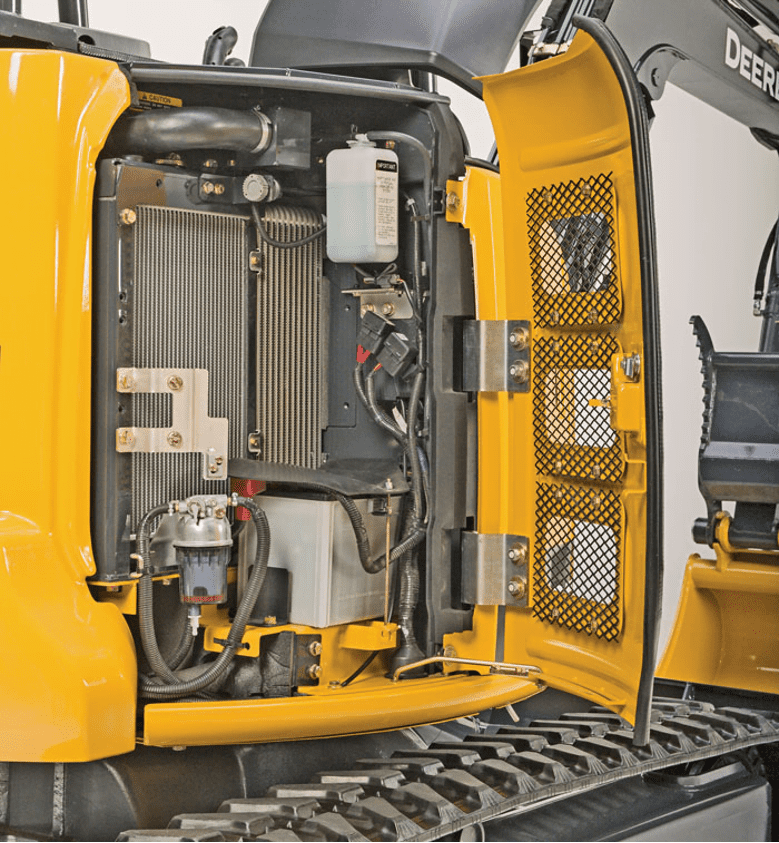

Hydraulic systems dissipate heat through the reservoir. Hence, the reservoir fluid level must be maintained at the correct level. Always check if there is any obstruction to the airflow around the reservoir. A basic example of obstruction is the build up of dirt or debris.

It is essential to check the heat exchanger and ensure that the core is not blocked. Its ability to distribute heat depends on the flow rate of the cooling air and hydraulic fluid. So check the performance of all cooling circuit components. Replace them if needed.

When fluid circulates in the area without performing the usual work, heat generates. This could be from a leaking cylinder or an incorrectly adjusted valve. So be alert to that sign and change suspicious heat-generating components.

It is a fact that high fluid temperature can damage seals. It can even reduce the hydraulic fluid’s service life. Besides that, this can also cause damage to system components through inadequate lubrication. This is the result of an excessive thinning process, which affects the oil film. You can install a fluid temperature alarm to prevent this. It will instantly warn you if there are any signs of dangerously high temperatures.

2. Slow Operation

A reduction in the performance is mostly the first sign that there is an issue with the hydraulic system. You will probably notice it when there are already longer cycle times or slow operation. Remember what we said earlier that hydraulic systems lead to faster equipment response. Therefore, a loss of speed means a loss of flow.

Flow can escape from the hydraulic circuit through internal or external leakage. Internal leakage is the hardest to find. This can occur in the pump or valves. Unless you have an X-ray vision, detecting internal leakage needs more human resources. On the other hand, external leakage is usually obvious. It sometimes manifests itself in burst hoses, so they are easy to find.

In addition, note that when there is internal leakage, there is a pressure drop. When there is a pressure drop, heat is generated. An infrared thermometer is a useful tool for identifying abnormal internal leakage. Humans do not have the ability to detect the exact temperature of equipment. Because of that, this thermometer can provide a signal for that problem. This can also pinpoint potential issues. Using that information will help you provide an immediate solution for your equipment. Incorrect hydraulic oil can also lead to pressure changes, decreasing the performance. An infrared test will also be able to pick this issue up.

Slow operation and high fluid temperature often show together. When fluid temperature increases, the viscosity decreases. When the viscosity decreases, internal leakage increases. When internal leakage increases, then the heat load increases.

3. Abnormal Noise

When your mini excavator begins to produce abnormal sounds, a problem is occurring. There is something wrong. It is important that you get to be alert to this symptom in order to prevent much bigger problems.

We have two main suspects for this problem—cavitation and aeration. Cavitation occurs when the hydraulic circuit demands more than what is being supplied. This will result in an absolute pressure on the part of the circuit, falling below the vapor pressure. This will lead to vapor cavities within the fluid that collapses when compressed. That situation will cause the knocking noise.

The consequences of cavitation in the hydraulic system can be dangerous. Cavitation will cause metal erosion, damaging hydraulic components. This can also contaminate the fluid. Worst case scenario, cavitation will cause mechanical failure of the system components.

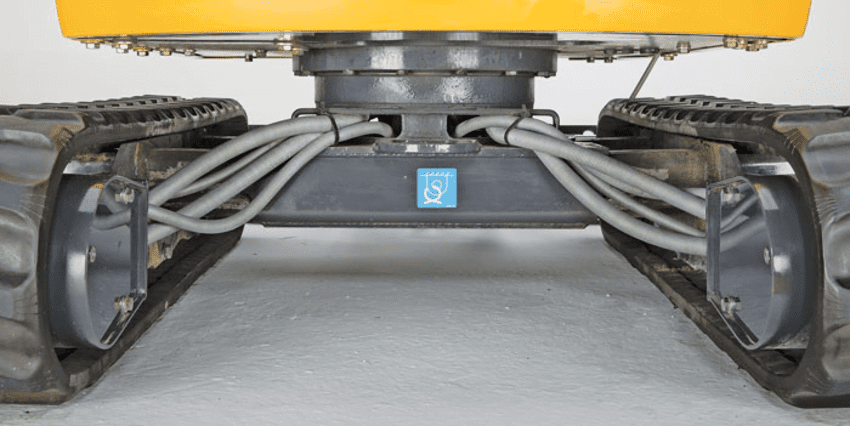

Cavitation can occur about anywhere within the hydraulic circuit. But, it is mostly seen at the pump. A clogged inlet strainer may cause the fluid to vaporize. If the pump has a filter or an inlet strainer, it should never be clogged. If a gate-type isolation valve is fitted, then it must be fully open.

Meanwhile, aeration occurs when the air contaminates the hydraulic fluid. The air in the hydraulic fluid will cause an alarming banging sound. You will notice the noise whenever it compresses or decompresses. Other signs of aeration are foaming of the fluid and irregular actuator movement.

When there is aeration, it fastens the degradation of the fluid. This will damage the system components due to the loss of lubrication. Overheating and burning of seals can also be the effects of aeration.

Air will enter the hydraulic system through the pump’s inlet. With that, make sure that the pump intake lines are in excellent condition. All clamps and fittings must be tight. Flexible intake lines can also become porous with age. So replace the old ones if needed.

How To Solve Hydraulic Problems on Mini Excavators?

Hydraulic systems have so many interrelated components. It then becomes difficult for most people to assess where the problem is coming from. Repair costs can be expensive, which is why operators often try to solve the problem first. If symptoms persist, then that is the time for them to reach out to experts. So to be practical, we listed out the basic troubleshooting process that you can follow. This will be valuable in solving your hydraulic problems. Treat it as a first-aid response to your mini excavators. But, keep in mind that this does not guarantee an accurate fix. Sometimes, the problem is bigger than what you expected it to be. So professional help is still encouraged.

Identify the Problem

The first step to solving the problem is to identify it first. The things we discussed above can be your guide in knowing the signs of hydraulic problems.

Gather Adequate Information

After identifying the problem, research it. You can take a look at its possible causes. You can also search for its effect on other systems so that you can prevent it from spreading. In short, be knowledgeable so that you can appropriately fix the problem.

Consult the Schematic, Maintenance, and Manual Records

Verify if you have the right schematic and repair manual for your mini excavator. That is going to be helpful as you try to mediate the hydraulic issues. A helpful schematic provides a list of all the components in the system. It has a diagram that will tell the relationship between them. It even shows the exact location of test points. So you should always keep these important records on hand in case of emergencies.

System Troubleshooting and Adjustments

The description is pretty self-explanatory. You have now identified the problem and researched about it. You are also done checking the repair manual. The next thing to do is to start fixing the actual system. This is the time for you to follow the repair guidelines and make the necessary adjustments.

Reliability Checklist

After solving the issue, the next step for you to do is to observe the equipment. It may take up to hours or days. Be vigilant of your mini excavator’s performance. Your ultimate goal here is to help make the equipment go back to its normal routine.

Bottomline

Hydraulic problems commonly cause headaches for operators. If left unattended, this can greatly damage your equipment. Given that mini excavators are not cheap, hydraulic problems can be a threat to your business.

As much as possible, educate yourself on the common hydraulic problem signs. It will help you in avoiding significant repair expenses in the future. The moment your mini excavator starts to show one of the symptoms above, begin to take action. Start the troubleshooting process or contact a reliable person. If the problem still occurs, then immediately approach an expert. It is better to treat early problems than severe ones.

I hope this article was able to give you an in-depth overview of hydraulic problems on mini excavators. If you love to see more articles like this, you may check out our Blog Page. You can also contact us for any inquiries, and we will gladly accommodate you.