Transfer carts overcome these challenges by providing a simple, safe and automated method of moving heavy loads. With transfer carts, there’s no need for additional manpower to push or pull the load; you simply load the cart and push a button.

A transfer cart is an industrial material handling vehicle designed to move heavy loads across factory floors. Powered by electricity, it provides a safe, flexible, and cost-effective solution for industries like warehouses, ports, and production workshops.

Let’s explore how transfer carts work, their types, and why industries increasingly prefer them.

What Is a Transfer Cart Used For?

Companies worldwide constantly seek safer and more efficient ways to transport heavy equipment and raw materials. This is where transfer carts come into play.

Transfer carts are used for moving large and heavy materials across workshops, warehouses, and production lines, reducing manual labor and improving efficiency.

Industrial transfer carts are common in steel plants, automotive factories, and warehouses. They help shift items such as steel coils, molds, or bulky parts that are difficult to move with forklifts. By minimizing manual handling, they improve workplace safety and productivity, making them a popular choice for modern material handling.

How Does a Transfer Cart Work?

Understanding how a transfer cart functions helps buyers select the right model for their business.

Transfer carts work by using electric batteries or cable reels to power wheels. They operate either on fixed rails or freely on smooth floors.

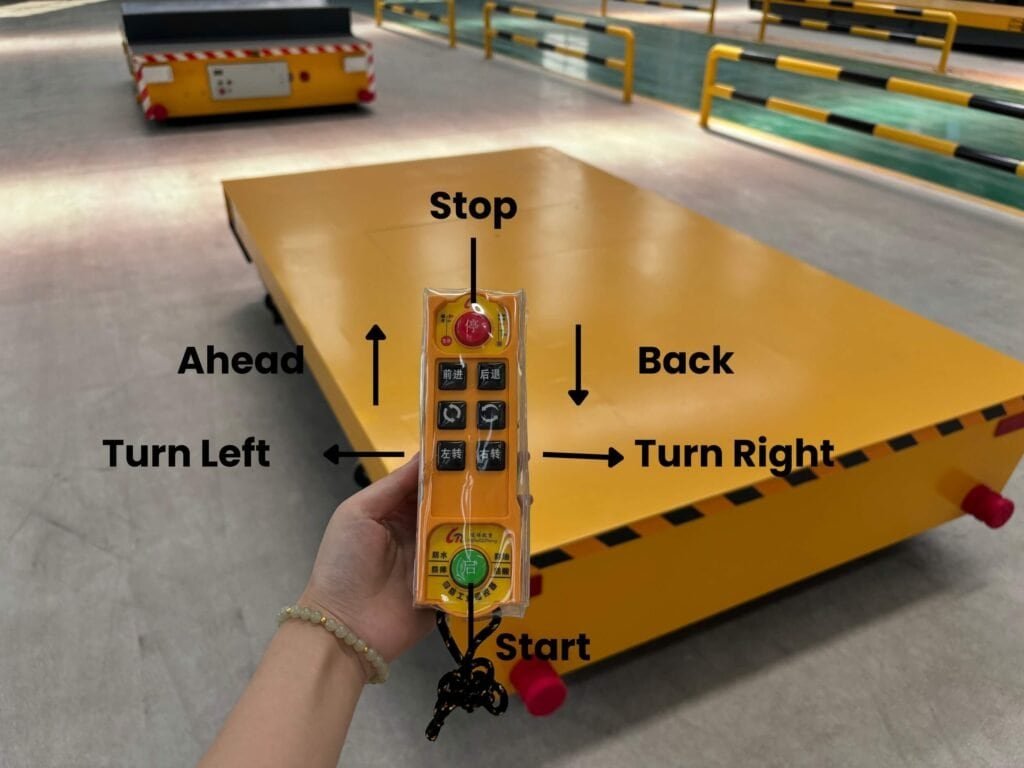

Rail transfer carts are designed to move along a fixed track, making them stable for repetitive tasks. In contrast, trackless transfer carts run directly on factory floors without rails, offering flexibility in movement. Both models use remote controls for forward, reverse, and even lateral driving, ensuring precise control with minimal manpower.

What Are The Types of Transfer Carts?

Not all transfer carts are the same. Different industries need different solutions for heavy load transport.

Main types include rail transfer carts, trackless transfer carts, coil transfer carts, and fully customized solutions for special material handling needs.

- Rail Transfer Cart: Best for continuous, straight-line tasks with heavy loads.

- Trackless Transfer Cart: Offers maximum flexibility, especially in plants with changing layouts.

- Coil Transfer Cart: Designed with special cradles to safely move cylindrical objects like steel coils.

- Customized Carts: Built for unique requirements, ensuring efficiency in specialized industries.

What Are The Advantages of Using a Transfer Cart?

Many businesses switch from forklifts to transfer carts because of the clear benefits they provide.

Transfer carts improve safety, reduce labor costs, and handle heavier loads more efficiently than forklifts, making them a smarter investment.

Unlike forklifts that require skilled operators, transfer carts are remote-controlled, eliminating the need for constant driver supervision. They reduce the risk of accidents in crowded workshops and can move much larger weights. Automated transfer carts also save time during peak production, preventing costly delays. Over the long run, this translates into higher productivity and lower operational costs.

Where Are Transfer Carts Used?

Transfer carts have become essential equipment in a wide range of industries

They are used in steel plants, automotive manufacturing, warehouses, ports, and logistics centers for moving heavy materials.

Steel producers use coil transfer carts to move hot or cold rolled coils safely. Automotive plants employ trackless transfer carts to shift car parts between production stations. Warehouses and ports rely on heavy load transfer carts to transport containers, pallets, and large goods. This adaptability explains why transfer carts are a preferred material handling solution worldwide.

How To Choose The Right Transfer Cart?

With many options available, buyers often wonder how to select the best transfer cart for their operations.

The right transfer cart depends on load capacity, working environment, floor conditions, automation level, and budget considerations.

For heavy, repetitive tasks in straight paths, a rail transfer cart is ideal. If flexibility is needed, a trackless transfer cart is better. Coil transfer carts are necessary for industries handling cylindrical goods. Buyers should also check certifications, after-sales support, and customization options. Choosing a reliable transfer cart manufacturer ensures both quality and smooth logistics.

Summary

Transfer carts make heavy load handling easier, safer, and more efficient. They are a flexible solution for modern industries seeking productivity and cost savings.

Contact Us To Buy Transfer Cart Now

If you want to buy a transfer cart, hiosen is definitely your best choice. Contact us to get the latest product quotes and customization information.