The mixer features a robust structural design that resists deformation, ensuring long-term operational stability. Both endplates are equipped with precision-machined bore holes for enhanced alignment and durability. Driven by dual motors and a high-efficiency hard-tooth surface gearbox, the system uses direct coupling to maximize transmission efficiency.

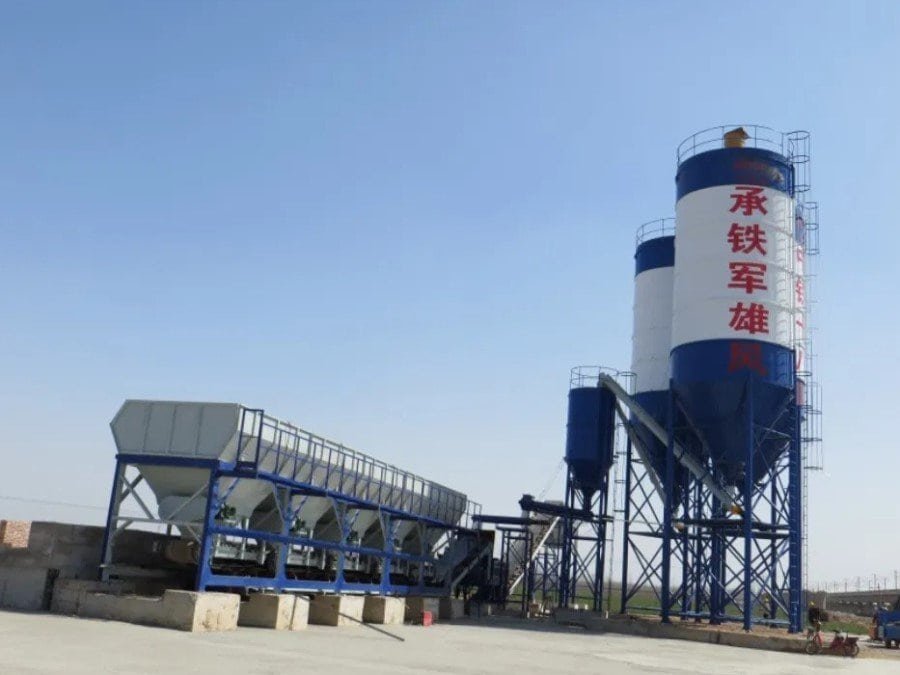

Taian HIOSEN Machinery Co., Ltd. is leading the asphalt mixing plant, concrete mixing plant and stabilized soil mixing plant industries as a trusted manufacturer and global exporter. By integrating cutting-edge international technology, the company consistently delivers high-performance solutions to support large-scale infrastructure projects at home and abroad. With a reputation for engineering excellence and reliable performance, Guangxin Machinery will continue to drive the progress of modern construction and roadbed development worldwide.

The double-shaft mixing system incorporates oversized shafts and extended mixing arms to deliver a higher mixing volume and longer effective mixing distance. This design guarantees superior blending performance and uniformity of the final material, ensuring consistent output aligned with the rated model capacity. Additionally, the multi-material discharge door is engineered for easy access and convenient cleaning, improving operational efficiency and maintenance convenience.

| Gross Weight | ≈30t |

| Covering Area (L x W) | 42×11=462㎡ |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

| Gross Weight | ≈30t |

| Covering Area (L x W) | 42×11=462㎡ |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

| Gross Weight | ≈32t |

| Covering Area (L x W) | 42×11=462㎡ |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

| Gross Weight | ≈48t |

| Covering Area (L x W) | 48×15=720m2 |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

| Gross Weight | ≈48t |

| Covering Area (L x W) | 48×15=720m2 |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

| Gross Weight | ≈50t |

| Covering Area (L x W) | 48×15=720m2 |

| Assembly Form | Detachable Modular |

| ControlModule | Auto/Semi-auto |

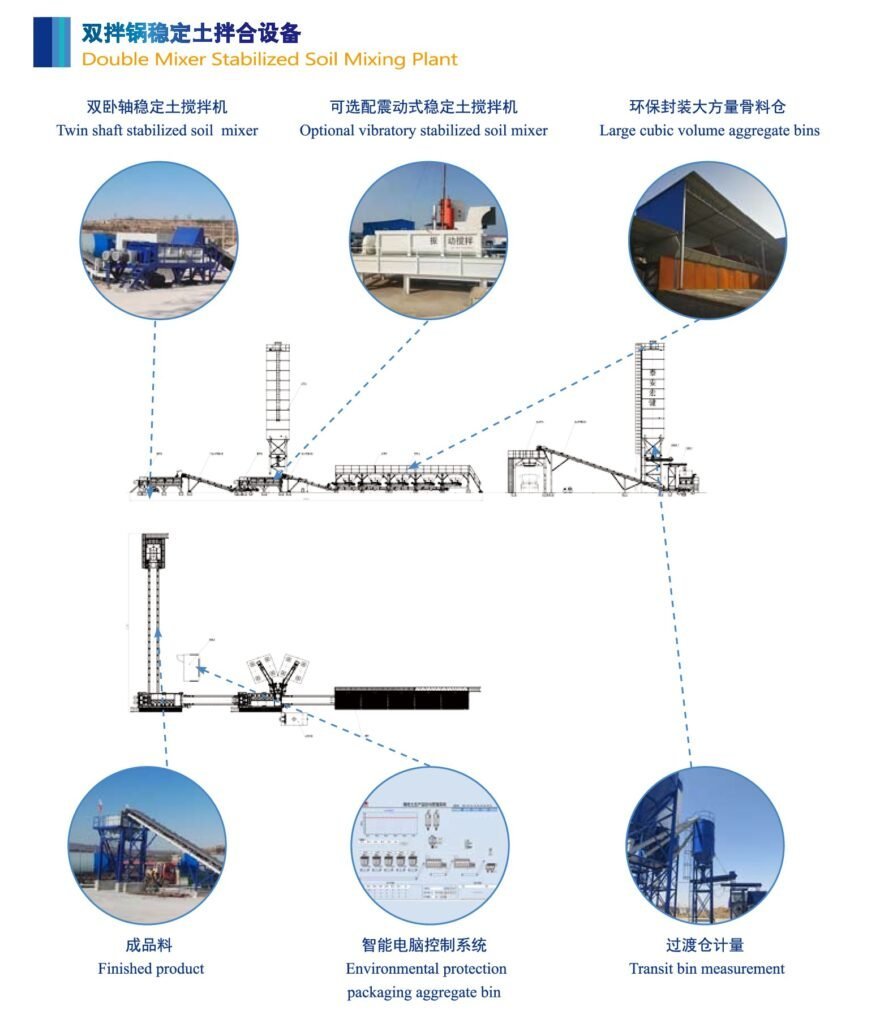

Integrated & Compact Design

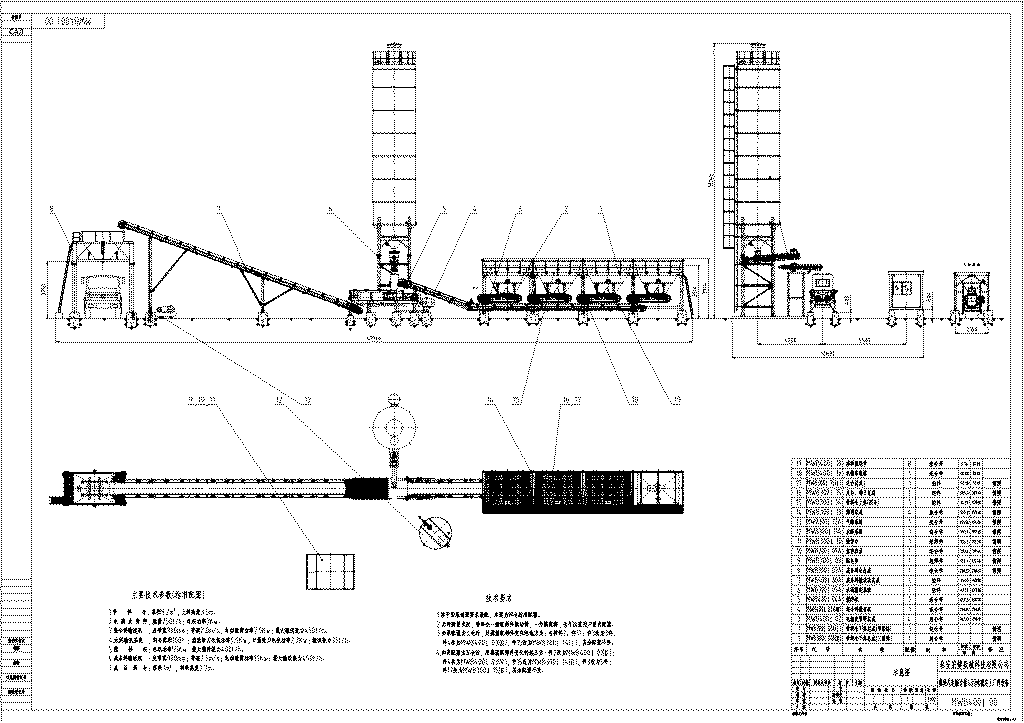

The plant is composed of five core systems: aggregate feeder, stabilizer feeder (cement/lime), water supply, mixer, conveying & storage unit, and an advanced electrical control system.

High-Precision Weighing System

Accurate ingredient measurement ensures consistent quality and optimized material usage.

Efficient & Uniform Mixing

Dual-shaft mixing delivers even blending and high overall performance. Trailer-mounted structure enables flexible on-site deployment.

Reliable Electrical Control

Features electromagnetic speed control for stable material flow. All components sourced from reputable brands like Schneider, CHINT, and LG.

User-Friendly Operation

Output and mixing ratios can be preset with ease. Supports both automatic and manual modes, with safety features such as fault alarms and emergency stop.

Available

1 year

1 year

Available

Rigid structure resists deformation, ensuring long service life.

Dual motor with high-efficiency hard-tooth gear reducer and direct coupling for optimal power transmission.

Extra-large shafts and extended mixing arms increase volume and effective mixing distance.

Guarantees uniformity of finished product and consistent output across all models.

Multi-material discharge door design allows easier maintenance and cleaning.

Composed of two or three rigid interlocked modules, offering structural strength and easy relocation.

Integrated with a low-positioned conveyor for space-saving installation and fast setup.

Equipped with external gear reducer for durable, low-maintenance operation.

Provides better stability and consistency than single-point sensors commonly used in the market.

Electrical components sourced from Siemens (Germany) and Danfoss (Denmark) for reliable performance and low failure rates.

Supports both manual and automatic control modes, with quick switching and fault alarm functionality for enhanced safety.

We offer specialized customization options such as mixing systems, aggregate bins screens, skirt weighing belts, powder measuring systems, water supply systems, etc. Our ISO-certified solutions can support capacities from 300 to 800 tons and are designed for large plazas, airports, municipalities and mining road construction projects.

| Modèle | MWB300 | MWB400 | MWB500 | MWB600 | MWB700 | MWB800 |

|---|---|---|---|---|---|---|

| Rated Capacity (t/h) | 300 | 400 | 500 | 600 | 700 | 800 |

| Main Power (kW) | 83 | 110 | 128 | 186 | 208 | 225 |

| Aggregate Size (mm) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

| Grading Types | 4–5 | 4–5 | 4–5 | 4–5 | 5–6 | 5–6 |

| Measuring Precision | Aggregate ±2%, Powder ±1% | Aggregate ±2%, Powder ±1% | Aggregate ±2%, Powder ±1% | Aggregate ±2%, Powder ±1% | Aggregate ±2%, Powder ±1% | Aggregate ±2%, Powder ±1% |

Enjoy unmatched speed and reliability through our fast, efficient shipping and robust inventory. At HIOSEN, we’re committed to delivering exceptional service that supports and elevates your construction projects—every step of the way.

Hiosen vous accueille chaleureusement pour visiter notre usine, où vous obtiendrez un aperçu de nos lignes de production de pointe, vous connecter avec notre équipe passionnée et voir de première main la qualité et l'innovation qui nous distinguent.

R: Nous sommes une usine.

R: Nous sommes une usine avec plus de 30 ans d'expérience de fabrication de machines de construction. Toutes nos machines sont fabriquées strictement selon les normes nationales et internationales, et nous testons rigoureusement chaque équipement avant la livraison.

R: Nous sommes un fabricant, pas une société commerciale, nous offrons donc des prix inférieurs à ceux des sociétés commerciales. Nous citons le plus faible que possible pour tout client, avec des remises supplémentaires basées sur la quantité.

A: We usually accept T/T (Telegraphic Transfer), Western Union, MoneyGram, L/C at sight, and Trade Assurance. 30% deposit before production, 70% payment before delivery.

R: Oui, la période de garantie pour nos machines est d'un an. Nous avons une équipe de services après-vente professionnelle pour résoudre rapidement et soigneusement vos problèmes. Un service après-vente est fourni et les ingénieurs sont disponibles pour les machines de service à l'étranger.

WhatsApp nous